Data-driven manufacturing is the need of the day. Digital transformation has entered the manufacturing industry and is changing the sector through data analytics. Business intelligence is the key to revamping manufacturing and improving quality, production, and returns.

The manufacturing industry has been looking at business intelligence with renewed interest. Data is usually scattered in the factory and manually fed into the system; it’s also offline until it is entered into the database.

Business intelligence provides a solution to bring the data together with minimum effort. It promises data collection, cleaning, and analytics to improve the manufacturing processes and increase returns. The manufacturing industry contributed 18% of the GDP in the Middle East in 2018. The countries have marked manufacturing as an integral part of their economic strategies to achieve their 2030 visions.

The ME region has the necessary infrastructure and connectivity to boost the manufacturing industry. Oxford Economics said that UAE’s industrial sector grew more than a third during the 2007-17 decade. Innovations and technological adaptations have been game-changers. Artificial intelligence, business intelligence, data analytics, etc., are said to take the manufacturing industry in the Middle East to newer heights.

The Gulf countries are using business intelligence services offered by offshore companies to revamp their existing systems and make the necessary changes to stay active in the competitive market. Let’s read in detail about the role of business intelligence in manufacturing and how data analytics can help manufacturing industries fulfill their role in contributing to the 2030 economic vision of the Middle East.

In simple terms, manufacturing is the process of producing products/goods using raw materials and tools. Biological or chemical processing may also be used to obtain the final product. Be it the production of a tiny toy, household appliances, or an automobile, converting raw materials into finished goods by following a systematic and pre-defined procedure is known as manufacturing.

However, the reality is much more complicated and involves a range of factors such as quality, cost, production cycle, duration, supply chain, and more. The path from acquiring raw materials to supplying finished goods to the market is filled with various elements that are not always under our control. Furthermore, the manufacturing processes are classified into three types:

MTS is where the finished goods are made in large numbers and held as stock in stores. These are widely used and always in demand. That said, manufacturing too much in surplus can lead to blocked capital and losses.

MTO is where the manufacturer waits for an order to start the production process. The clients/ customers have to wait until the production cycle is complete and the end product is handed over to them.

MTA is a combination of MTS and MTO. The manufacturer has a stock of the parts required to assemble the final product. The assembling will be done only when an order is placed. This not only reduces the time to deliver the product to the customers but can leave the manufacturer with excess parts if there are no orders.

How a manufacturer manages the processes and stock determines the success of the business. Business intelligence helps manufacturers use historical and real-time data to correctly anticipate the market demands and adjust production accordingly.

Business intelligence is a set of procedures, techniques, and software used to convert raw data into meaningful insights. BI allows manufacturers and enterprises to increase their business efficiency by making required changes to their systems and processes.

Every industry requires business intelligence to analyze data and derive actionable insights. These insights help businesses to make better decisions in a quick time and stay relevant in the competitive markets. Business intelligence is the use of data and data analytics to gather valuable information. BI for the manufacturing industry is also called manufacturing intelligence or manufacturing analytics.

The manufacturing industry needs to streamline and balance machine operations, supply chain, and logistics to get the desired results. The main aim of the manufacturing industry will be to reduce production costs without compromising the quality standards or delaying the production cycle. To achieve the goal of reducing costs and increasing production, the manufacturer needs to rely on the data-driven model to make decisions.

This is possible when the data flow is aligned within the manufacturing unit and bridges the gap between data, systems, and employees. BI and data analytics give manufacturers the necessary tools and insights to use data effectively and make the right decisions for the business.

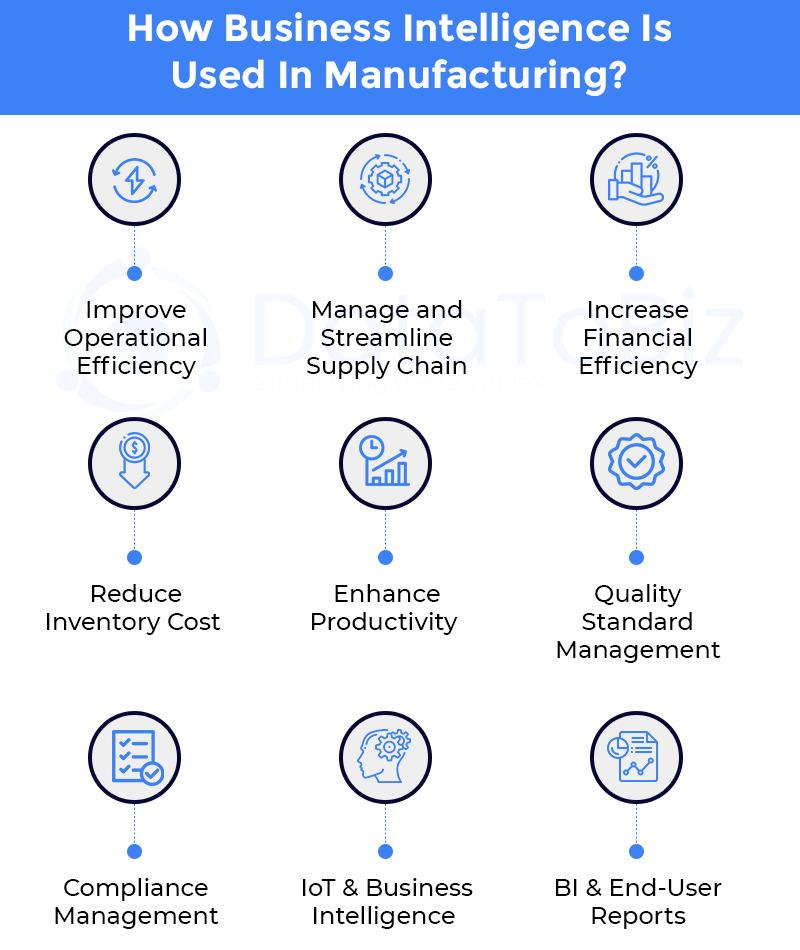

The use of business intelligence in manufacturing can be seen at every stage, from sourcing raw materials to supplying the final goods to end-users. Since most manufacturers already have the ERP system in place, adopting a BI and data-driven model is not too complicated.

Hiring the services of a business intelligence developer will help manufacturers understand the ways to implement BI and data analytics to derive accurate insights.

Operational efficiency is a must for a manufacturer to survive the competition in the markets. However, it is possible only when a business knows what changes to make and which processes to continue.

While data is available in abundance, using the data efficiently to gain in-depth insights into the existing operations of the manufacturer can be achieved through business intelligence. BI reduces the time taken to analyze data and derive reports, thus providing the management with the necessary information to make changes on time.

A manufacturer works with various third-party vendors, suppliers, carriers, distributors, etc. A delay at any point in the supply chain will lead to disruptions, postponements, and losses throughout the production cycle. It could lead to product failure or put the manufacturer at a disadvantage.

Business intelligence gives insights into suppliers, transporters, deliveries, expenses incurred during distribution, and so on. The reports can be used to choose reliable suppliers and freight partners and plan the production cycle to release the finished goods into the market when the demand is high.

Improving ROI is vital for a manufacturer. Resource optimization will directly impact returns. But making the wrong decision can lead to losses. Business intelligence provides manufacturers with reports on the cost of raw materials, production costs, etc., to help them identify the best way to increase the efficiency of the value chain. Sometimes, changing the supplier or eliminating an unwanted step from the supply chain can make a business more financially efficient.

Surplus stock and lack of inventory are two sides of the same coin. Not having enough stock when there is high market demand and having excess stock when there is no market demand gives the same results for the manufacturer.

Business intelligence helps avoid both instances by deriving insights to determine the optimal inventory level. Manufacturers can track inventory in real-time while effectively managing issues related to defective goods, warehousing, stock turnover, and distribution.

Knowing the productivity of an employee, machine, team, and department can help manufacturers find ways to increase production without affecting quality. Business intelligence tools track and monitor the individual performance of workers, supervisors, machines, etc., and generate reports to help identify the weak areas and make changes.

Quality assurance and testing are crucial in the manufacturing industry. A business that produces in bulk but doesn’t adhere to the quality standards cannot survive the competition for long. Business intelligence will help track quality across the production cycle and maintains a record of the number of goods being discarded against the ones that clear quality testing. BI allows manufacturers to maintain quality right from the first stage to the last.

Manufacturers need to follow the safety standards recommended by the authorities to ensure that workers are not at risk. The safety regulations depend on the type of products being manufactured. For example, products that require chemical processing tend to require more safety features.

Business intelligence streamlines data flow and provides valuable information to the manufacturers. This gives the management more control over the processes and makes it easier to adhere to the industry-wide safety regulations.

The Internet of Things (IoT) is being widely adopted by manufacturers from around the world. The IoT sensors collect production data from the machinery, which is processed by BI tools to derive insights in real-time.

From performing predictive maintenance to increasing worker safety in factory environments, business intelligence and IoT can be used to add value to the manufacturing business.

Business intelligence tools can be used by mid-level employees and supervisors to get a micro and macro view of the production cycle. It makes data easily accessible to employees and helps them make day-to-day decisions.

Data analytics in manufacturing or manufacturing analytics are a part of digitally transforming the manufacturing industry. Manufacturers are using real-time data and advanced analytics to gather in-depth information about every aspect/ element of their business.

Manufacturing analytics can help the industry in various ways, such as:

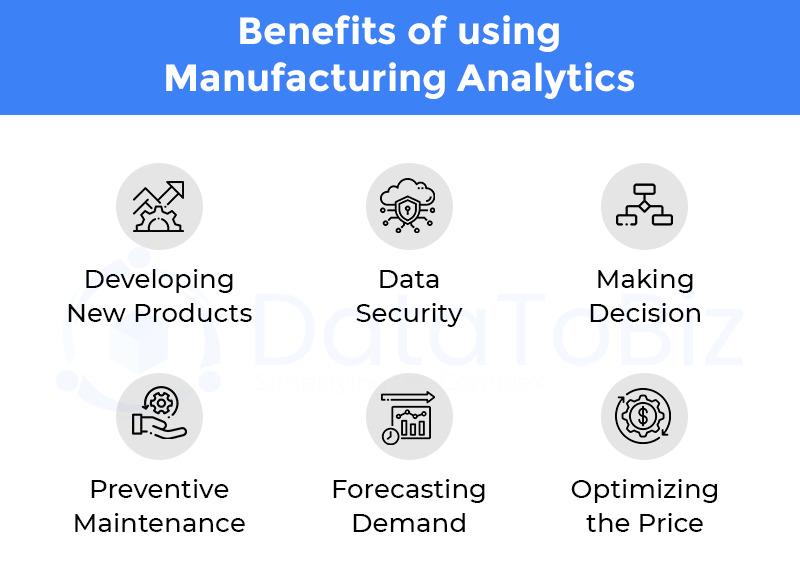

Developing New Products: Developing new products or upgrading existing ones requires research and investment. Using customer and market data for analytics will give manufacturers a definite idea about what kind of products/ features will be a success among the target audience.

Data Security: Manufacturers cannot ignore the importance of data security in today’s world. The cybercrime rate is high, and manufacturers need to identify the weak points in their systems to develop a multi-layered security protocol to prevent sensitive data from being breached.

Making Decision: BI and data analytics help with short-term, mid-term, and long-term decision-making to achieve the desired goals. Historical and real-time data can be used to get the full picture of the situation. This allows manufacturers to stay in control and grab more opportunities.

Preventive Maintenance: Manufacturers can save costs and increase machinery’s life by performing preventive maintenance. There is no need to stop work due to machinery breakdown as the defect will be caught at an earlier stage and prevented from becoming a major issue.

Forecasting Demand: Knowing the changing demand in the market help manufacturers moderate their supply accordingly. They can increase or decrease production based on the demand forecasting reports.

Optimizing the Price: The success of a product also depends on its price. Understanding how much a product should cost, when to reduce/ increase the price, and how much to change will decide the revenue of the manufacturer. Analytics gives a comprehensive insight into pricing and helps arrive at the exact value.

The manufacturing industry in the Middle East is undergoing several changes and developments. Offshore business intelligence companies are playing a vital role in helping manufacturers choose the right BI tools and data analytical dashboards to streamline the overall systems and processes in the enterprise.

Business intelligence can help manufacturers reduce costs, optimize resources, and increase returns while improving the quality standards of production by removing bottlenecks.